List of Services

-

KG WHEELS

New grinding wheel that contains nano-crystaline ceramic abrasive for precision grinding of tough steels and superalloys.

-

HA SLOTTING WHEELS

For applications such as slotting, groove edge finishing.

-

BENCH & PEDESTAL WHEELSList Item 1

Bench and pedestal wheels provide metal removal, deburring, shaping and sharpening needs. Available to fit many sizes and specification of machines, our variety of abrasive selection meets the application need for high speed tool steels, carbon steel, non-ferrous metals and carbide tooling.

-

FOUNDRY SNAGGING WHEELSList Item 2

Foundry snagging wheels are used for getting rid of unwanted metal after casting such as gates, risers, flashing, stubs, fins and parting lines process. Coarse and durable wheels are applied because the tolerance is not critical.Snagging wheels are for benchstand, pedestal, floorstand and swing frame grinders.

-

INTERNAL GRINDING WHEELSList Item 3

Internal grinding refers to the gridning of bores or holes. Requirement of internal grinding range from very rapid removal of stock to processes capable of generating size and concentricity measured in millionths of an inch.

-

SURFACE GRINDING WHEELS(STRAIGHT TYPE)

Surface grinding with straight and recessed wheels on machines with a rotary or reciprocating table results in larger contact area than in cylindrical grinding.

-

SURFACE GRINDING WHEELS

Surface grinding with straight and recessed wheels on machines with a rotary or reciprocating table results in larger contact area than in cylindrical grinding.

#122 Type 2-Cylindrical

#123 Type 6-Cup Wheels

-

SEGMENTSList Item 4

Segments are used for surface grinding. Their benifits include rfee cutting, more stock removal because of better chip clearance and penetration of coolant and gives you precision, better surface finish, even on the thinnest workpieces.

-

DISC SURFACE GRINDING WHEELS D.S.G

D.S.G wheels are applied for machines which essentially grind flat surfaces and used as a pair called D.S.G. The wheels are mounted against steel machine plates so that the grinding is performed on the flat sides of the wheel.

-

CYLINDRICAL GRINDING WHEELS

Cylindrical grinding refers to the grinding of outer surface of work pieces, even though the finished workpiece is not a cylinder.

-

ROLL GRINDING

Rolls are widely used on rolling machines in steel mills, paper mills, aluminum, brass, copper industries.

-

CENTRELESS GRINDING WHEELS

Achieve extremely close tolerances with Kinik centerless grinding wheels. Whether through feed, end feed or in feed grinding, our centerless grinding wheels give a precision finish.

-

CRANKSHAFT GRINDING WHEELS

Crankshaft grinding wheels are applied throughout many industries such as the automotive, truck, diesel, aircraft, small engine manufacturing.

-

CAM GRINDING WHEELS

Cam grinding demands free cutting wheels with good form holding abilities togather witht he ability to maintain tight surface finish tolerances. Both resinoid and vitrified bonded wheels are used, depending on the material used and surface finish required.

-

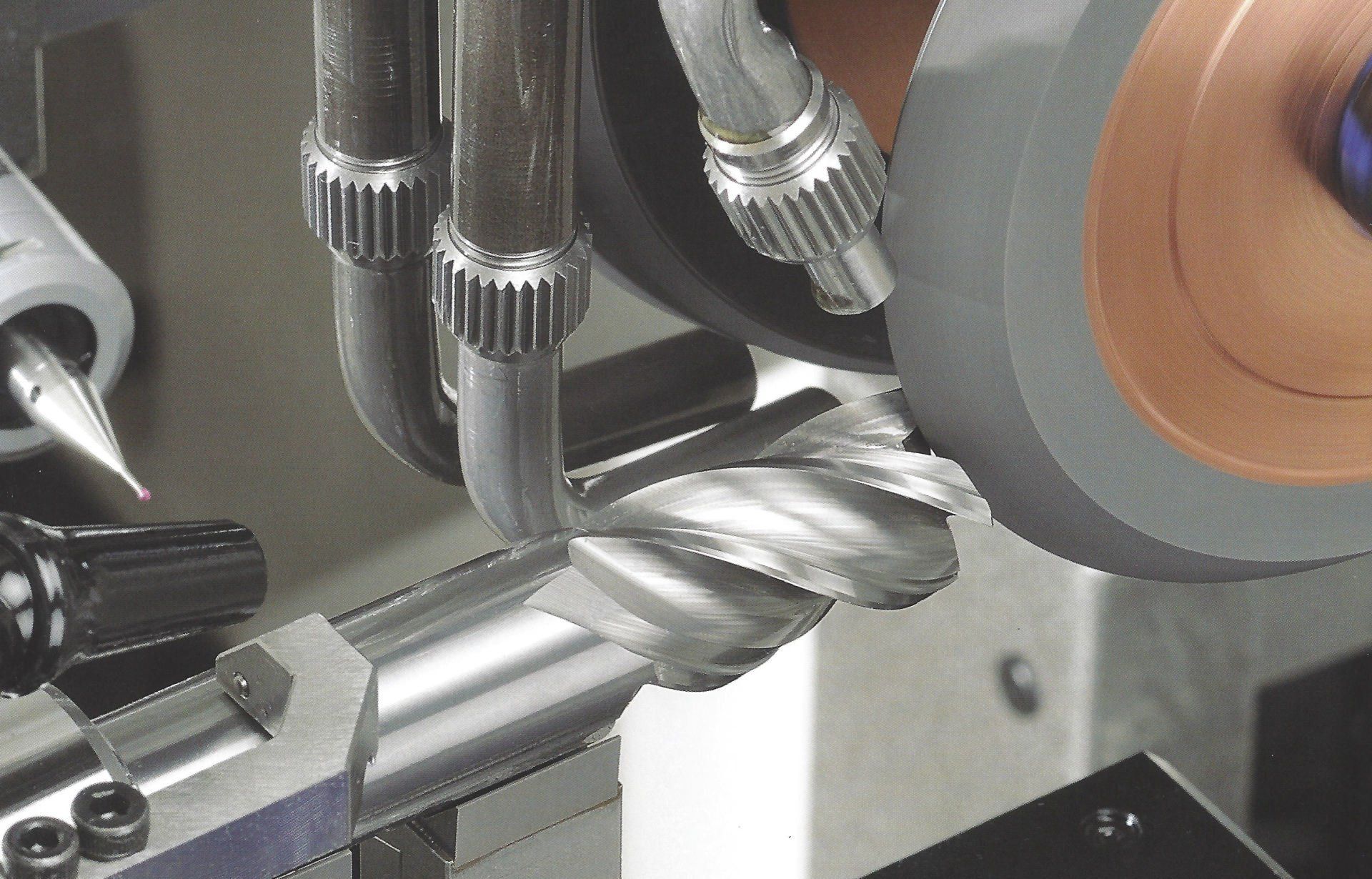

TOOL GRINDING WHEELS

Available to fit many sizes and specification of machines with speed, quality and finish in mind.

-

SAW GUMMING WHEELS

Saw gumming wheels are primarily used for shaping and resharpening of various types of saws, principally in the timber and woodworking industries as well as saw manufacturers

-

VALVE SEAT, VALVE FACE GRINDING WHEELS

Valve seat, valve face and valve end grinding wheels bring you a full assortment of replacement wheels for all major manufacturing equipments.

-

GEAR GRINDING WHEELS

Grinding wheels are used to generate the desired profile of gear teeth after heat treatment. The machine and gear type determine the shape of the grinding wheel.

-

MG BOND WHEELS

MG bond wheels(Nagnesia Oxychloride) are suitable for grinding cutting edge of all knifes, as well as surface grinding in thin and light workpieces

-

HONING STONES

They are designed to remove stock quickly. Our honing stones/sticks are manufactured to fit virtually every machine and honing application in today’s honing industry.

-

SUPERFINISHING STONES

An abrasive process for the superfine machines of sealing and bearing surfaces, piston rods and rollers.

-

POLISHING STONES

For modifying or polishing metal molds, cutting tools or jigs. To prevent scratches and get better surface finish on workpiece.

-

SHARPENING STONES

Sharpening stones are used for resharpening wood working or metal working tools such as knifes, siccors, drills and knives used in kitchen.

-

DRESSING STICKS

Dressing sticks are used primarily in off-hand dressing of diamonds and CBN wheels and in offhand truing and dressing of medium grit, medium and soft grade vitrified grinding wheels .

-

MOUNTED WHEELS

Primarily used for off hand application in foundries, steel mills, metal working and stone industries.